Fiber CCL (Fiber Casing Collar Locator)

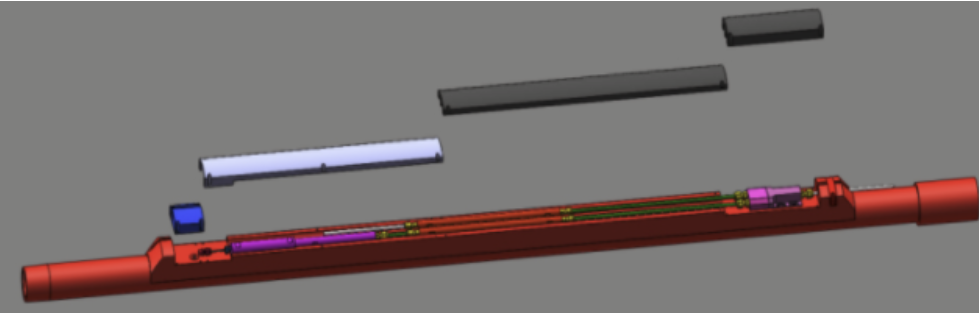

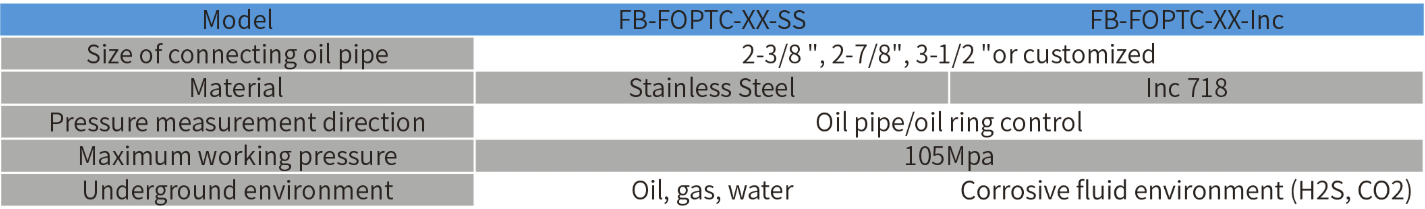

The fiber optic PT gauge mandrel is a critical downhole component designed to house and protect the pressure and temperature (PT) gauge while ensuring secure integration with the tubing string during well operations. Constructed from high-quality stainless steel, this mandrel provides exceptional mechanical strength, corrosion resistance, and longevity in harsh downhole environments.

The fiber optic PT gauge mandrel is engineered to accommodate various tubing sizes, including 3-1/2", 2-7/8", and 2-3/8" tubing strings, making it versatile for different wellbore configurations. Its precision-machined body ensures a secure and leak-proof connection to the tubing, minimizing the risk of failure under extreme downhole conditions. The mandrel is designed with optimized internal and external threading, ensuring compatibility with industry-standard tubing connections while providing ease of installation and retrieval.

The optional Inconel material construction enhances the mandrel’s resistance to high-pressure, high-temperature (HPHT) environments, as well as exposure to corrosive fluids such as hydrogen sulfide (H2S) and carbon dioxide (CO2). This ensures long-term stability and reliability in both conventional and enhanced oil recovery (EOR) operations.

The primary function of the mandrel is to safely encapsulate and support the fiber optic PT gauge, shielding it from mechanical damage while allowing seamless transmission of real-time pressure and temperature data from the reservoir. By integrating the PT gauge within the mandrel, fiber optic cables are protected from excessive bending, vibration, and potential breakage, ensuring consistent signal integrity. The mandrel also features dedicated cable routing mechanisms, allowing for efficient fiber optic deployment without interfering with tubing integrity or wellbore operations.

The fiber optic PT gauge mandrel is an indispensable tool for downhole pressure and temperature monitoring, offering a durable, corrosion-resistant, and mechanically robust solution for harsh well environments. Its versatility in tubing compatibility, seamless integration with fiber optic systems, and high reliability in HPHT conditions make it a preferred choice for modern oil and gas operations. The site testing structure presets at the gauge connection and penetration hole of the mandrel body, the field service guy can test the seal of the gauge pressure port connection on site after he installed the PT gauge on the mandrel.

Y-Splice on PT Gauge Mandrel

Overview

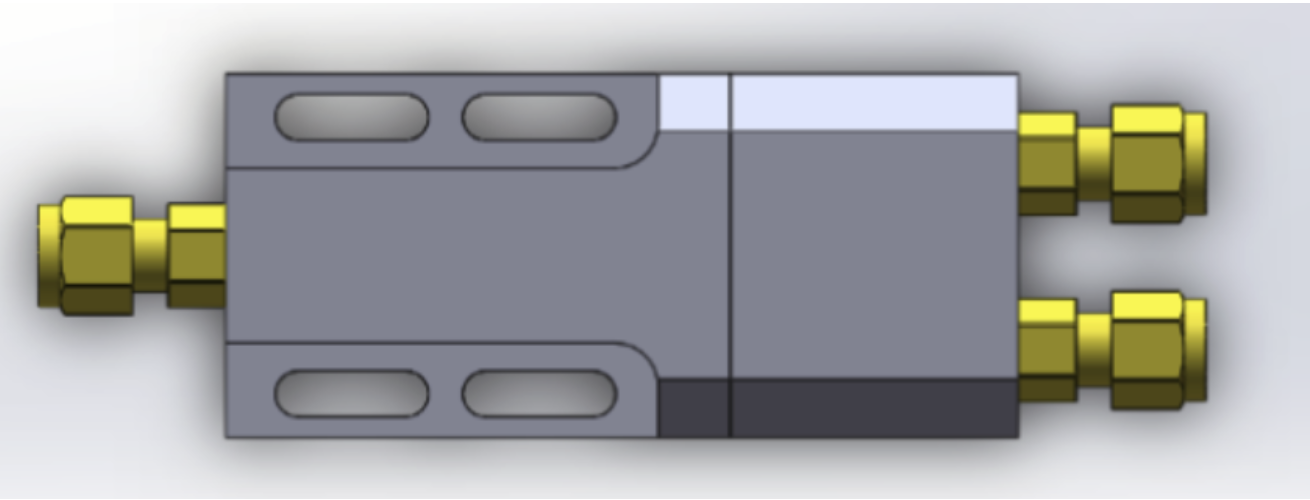

The Y-splice for fiber optic cable is used to enable fiber branching while maintaining the multiple fibers combined with a signal cable in downhole applications. Made from stainless steel or Inconel, it provides durability, corrosion resistance, and mechanical protection in high-pressure and high-temperature (HPHT) environments. This splice tool is specifically designed for installation on a PT gauge mandrel, ensuring secure fiber routing and protecting connections from mechanical stress.

Features

1.Easy installation

oSuited to Fiber-Opto’s PT gauge mandrel.

oEasy connection with any kind of the capillary layer fiber optic cables with the fittings.

2.Compact structure

oIntegrated structure design for HTHP downhole environment application.

oUse the fittings fastening mechanisms to fix the splice onto the mandrel to provide the metal seal to the cable and internal structure against the downhole high pressure.

oOptional material of the Y splice can used for the different DH environment, like H2S, CO2 and etc.

3.Final Inspection & Testing

oSecure all connections and check alignment.

oPerform an optical continuity test to verify signal transmission.

oEnsure pressure integrity before deployment into the well.

This stainless steel Y-splice ensures reliable fiber branching and long-term performance in harsh downhole conditions.

To list

To list