Fiber Optic Pressure / Temperature Gauge

Principle of Fabry Perot cavity fiber optic pressure gauge technology

The Fabry Perot cavity sensor is based on the principle of optical interference, and its core structure is a small cavity composed of two highly parallel reflecting surfaces.

▪ When external pressure or temperature changes, the length of the cavity will undergo extremely small changes, resulting in correspond- ing shifts in the interference fringes of the reflect-ed light signal.

▪ Through high-precision spectral demodulation technology, interference signals can be converted into precise values of pressure and temperature, achieving high-precision downhole measure-

ments.

Compared with traditional strain gauges or electronic sensors, Fabry Perot cavity fiber optic sensors require no power supply, are resistant to electromagnetic interference, corrosion-resistant, and high-temperature, making them particularly suitable for complex environments in oil and gas wells.

Optimization of underground instrument packag- ing and high temperature stability

The long-term stability of fiber optic Pressure Temp gauge depends on sensor packaging technology and structural design.

▪ After years of optimization, the packaging

materials and structure of the system have been greatly improved, using high-temperature alloy materials and fully sealed packaging technology to greatly suppress long-term drift problems.

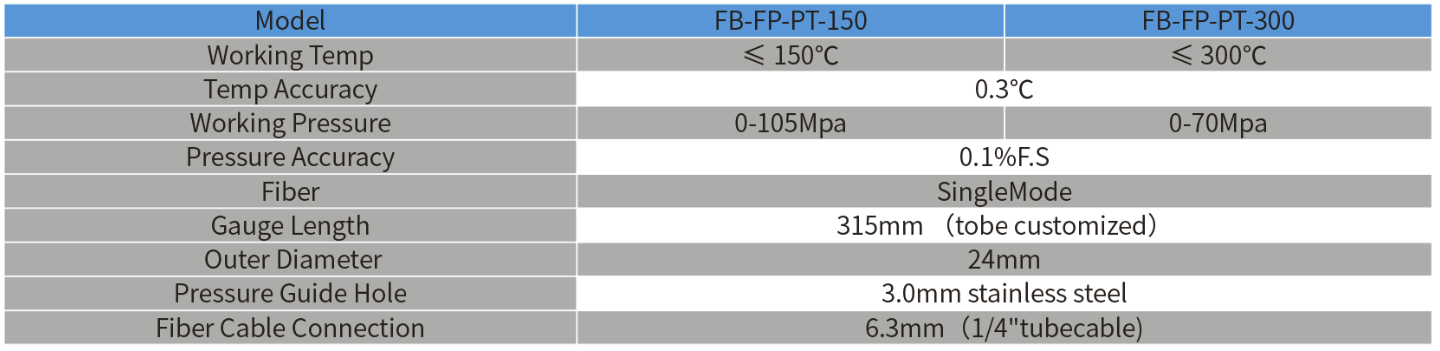

▪ In high-temperature underground environ- ments of 150 °C and 300°C, the instrument can still maintain extremely low zero drift, achieving long-term accurate monitoring.

▪ The permanent installation and application of this instrument in Tuha Oilfield has achieved a

continuous operating life of more than 5 years, far superior to traditional electronic pressure

thermometers, proving its excellent high-tempera- ture stability.

Typical application scenarios

▪ This fiber optic downhole pressure and

temperature monitoring system can be widely applied to:

▪ Long term monitoring of oil well pressure and temperature

(Conventional oil wells, gas wells, injection wells)

▪ Ultra deep and high-temperature wells

(Suitable for environments of 150 ° C and above)

▪ Steam assisted heavy oil extraction well (Applicable to SAGD and CSS processes)

▪ Dynamic monitoring of oil and gas reservoirs (Realtime monitoring of formation pressure and temperature changes, optimizing mining strate- gies)

▪ Integrity assessment of wellbore

(Analyzing wellbore status through abnormal pressure to prevent underground accidents)

To list

To list