Fiber optic monitoring for injection & production profiling of gas storage wells

The braided fiber optic cable is deployed into the well with weight bars and standard well control equipment

This gas storage well has different injection and production volumes for each pay zone under various production conditions. The operator has a strong demand for understanding the gas absorption and contribution of each pay zone of the reservoir under different production flow rate.

The fiber optic cables, logging instruments, and weight bars were deployed into the well by standard wireline unit and process with the pressure control equipment. DAS,DTS, and pressure gauges are used in conjunction to monitor production dataunder different gas injection conditions.

Full layer monitoring of each depth section of the wellbore

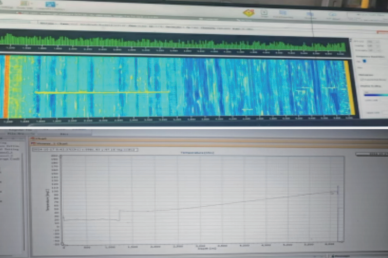

The DTS and DAS monitors temperature changes at various points through DTS and acoustic vibrations at various points through DAS. It also monitors temperature and pressure changes at the bottom of the well through pressure and temperature gauge, displays and records distributed measurement data in real time. During the testing period, the well adjusted three different gas injection systems and two fast opened/closed well cycles, with a total measure- ment time of 98 hours. The monitoring accuracy of the optical fiber reached spatial accuracy of 0.5m and temperature accuracy of 0.1 ℃.

Prev

Prev

Next

Next

To list

To list